Technical Capabilities

Projects |

Technical Capabilities |

||

Number of layers |

Mass production:2-24 layers/Sample:30 layers |

||

Plate thickness |

Mass production:0.6-3.2mm/Sample:10mm |

||

Material type |

FR-4(Regular FR4,Medium Tg,High Tg)、CEM-3、Aluminum Base |

||

Minimum line width/line spacing |

Inner layer |

0.5 OZ Base copper:3/3mil |

|

1.0 OZ Base copper:4/4mil(Partial line3/3mil) |

|||

2.0 OZ Base copper:6/6mil |

|||

Outerlayer |

ENIG PCB |

0.5 OZ Base copper:4/4mil(Partial line3/3mil) |

|

1.0 OZ Base copper:5/5mil(Partial line4/4mil) |

|||

2.0 OZ Base copper:8/8mil |

|||

HASL PCB |

0.5 OZ Base copper:4/4mil(Partial line3/3mil) |

||

1.0 OZ Base copper:5/5mil(Partial line4/4mil) |

|||

2.0 OZ Base copper:8/8mil |

|||

Max copper thickness |

Production:3OZ(UL)/Sample: 12OZ(Sample) |

||

Vinimum aperture |

Mechanical drilling 8mil (0.20mm), Finished 4mil (0.10mm) |

||

Max size (Finished product) |

650*1300mm |

||

Max finished product thickness to diameter ratio |

15:1 |

||

Surface Finishing |

HASL、Lead-free-HASL、ENIG、OSP、Gold-finger |

||

Impedance tolerance |

±10% |

||

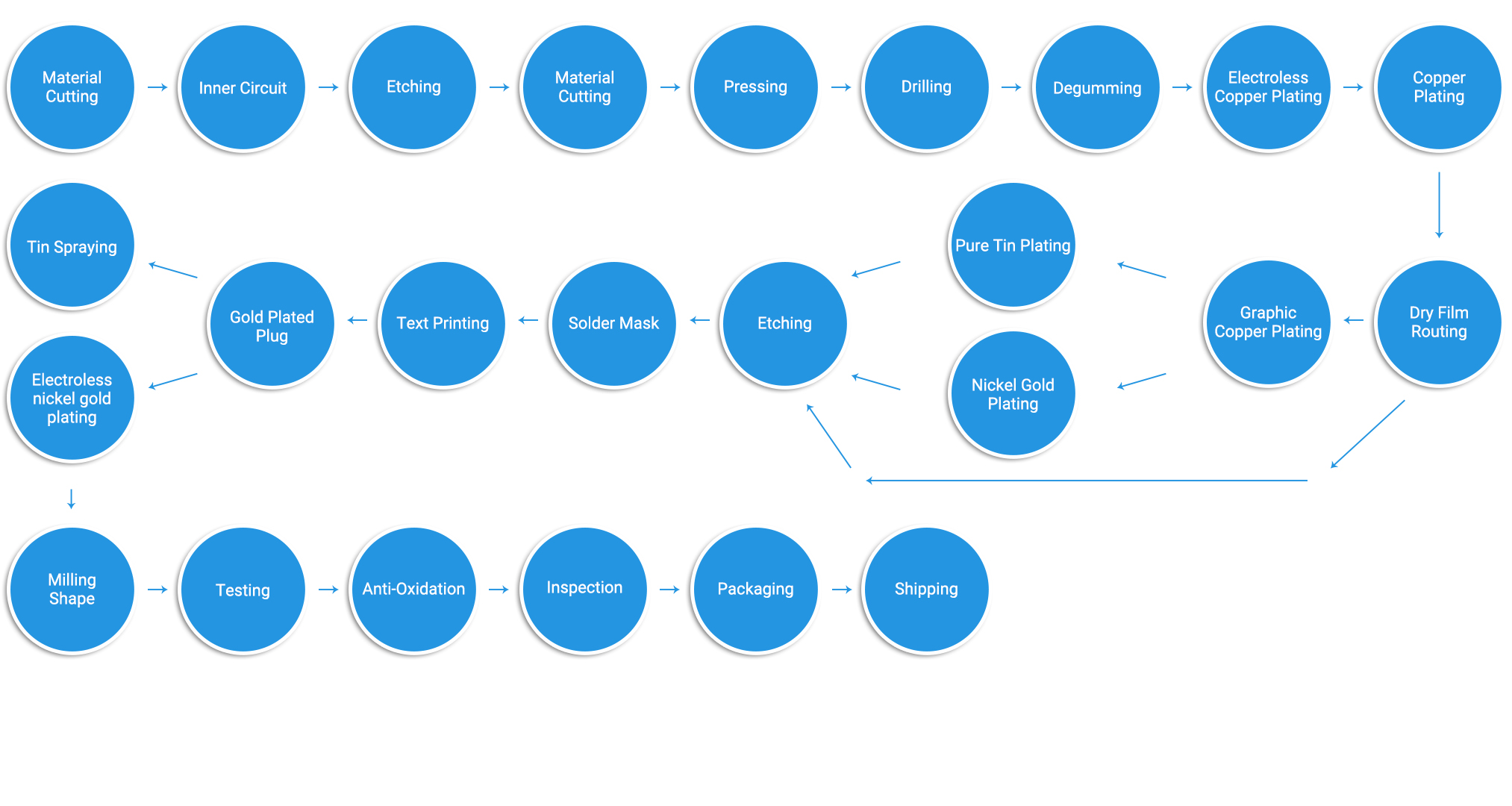

Process Production Video

Service Process

1. Requirements collection and preliminary communication

Customer demand collection: Communicate with customers to understand their specific circuit board needs, including circuit board type (such as single-layer board, double-layer board, multi-layer board, etc.), size, material, process requirements, production quantity, delivery time, etc. .

Preliminary quotation: Based on customer needs, a preliminary quotation and delivery estimate will be given.

2. Technical Assessment and Confirmation

Technical evaluation: Technical evaluation of design files (such as Gerber files, PCB files, etc.) provided by customers to confirm their manufacturability and compliance.

Design optimization suggestions: If there are areas that can be optimized in the design, we will provide optimization suggestions to help customers reduce costs and improve product quality.

Sample production and confirmation: If necessary, make samples for customer confirmation to ensure that the product meets their requirements.

3. Contract signing and order confirmation

Contract signing: After both parties reach an agreement on price, delivery time, quality standards, etc., a formal contract is signed.

Order confirmation: After the customer pays the advance payment or deposit, the order is confirmed and the production process is started.

4. Production and manufacturing

Material Procurement: Purchasing the required materials according to the order requirements to ensure that the material quality meets the standards.

Production and processing: Processing of circuit boards according to customer requirements and design documents.

Quality inspection: During and after the production, multiple rounds of quality inspection are conducted to ensure that the quality of the circuit boards meets the standards.

5. Delivery and Settlement

Shipping: Ship the circuit board to the customer according to the delivery date agreed in the contract.

Final payment settlement: After receiving the goods, the customer pays the final payment.

6. After-sales service

Technical support: Provide technical support to customers and answer questions they encounter during use.

Quality Assurance: Provide after-sales services such as repair and replacement for quality problems caused by production reasons.

7. Maintenance and expansion of customer relationships

Customer satisfaction survey: Regularly send satisfaction questionnaires to customers to collect customer feedback to improve service quality.

New customer development: Find new customers through various channels (such as exhibitions, the Internet, etc.) and expand business scope.