Technical Capabilities

Projects |

Technical Capabilities |

||

Number of layers |

Mass production:2-24 layers/Sample:30 layers |

||

Plate thickness |

Mass production:0.6-3.2mm/Sample:10mm |

||

Material type |

FR-4(Regular FR4,Medium Tg,High Tg)、CEM-3、Aluminum Base |

||

Minimum line width/line spacing |

Inner layer |

0.5 OZ Base copper:3/3mil |

|

1.0 OZ Base copper:4/4mil(Partial line3/3mil) |

|||

2.0 OZ Base copper:6/6mil |

|||

Outerlayer |

ENIG PCB |

0.5 OZ Base copper:4/4mil(Partial line3/3mil) |

|

1.0 OZ Base copper:5/5mil(Partial line4/4mil) |

|||

2.0 OZ Base copper:8/8mil |

|||

HASL PCB |

0.5 OZ Base copper:4/4mil(Partial line3/3mil) |

||

1.0 OZ Base copper:5/5mil(Partial line4/4mil) |

|||

2.0 OZ Base copper:8/8mil |

|||

Max copper thickness |

Production:3OZ(UL)/Sample: 12OZ(Sample) |

||

Vinimum aperture |

Mechanical drilling 8mil (0.20mm), Finished 4mil (0.10mm) |

||

Max size (Finished product) |

650*1300mm |

||

Max finished product thickness to diameter ratio |

15:1 |

||

Surface Finishing |

HASL、Lead-free-HASL、ENIG、OSP、Gold-finger |

||

Impedance tolerance |

±10% |

||

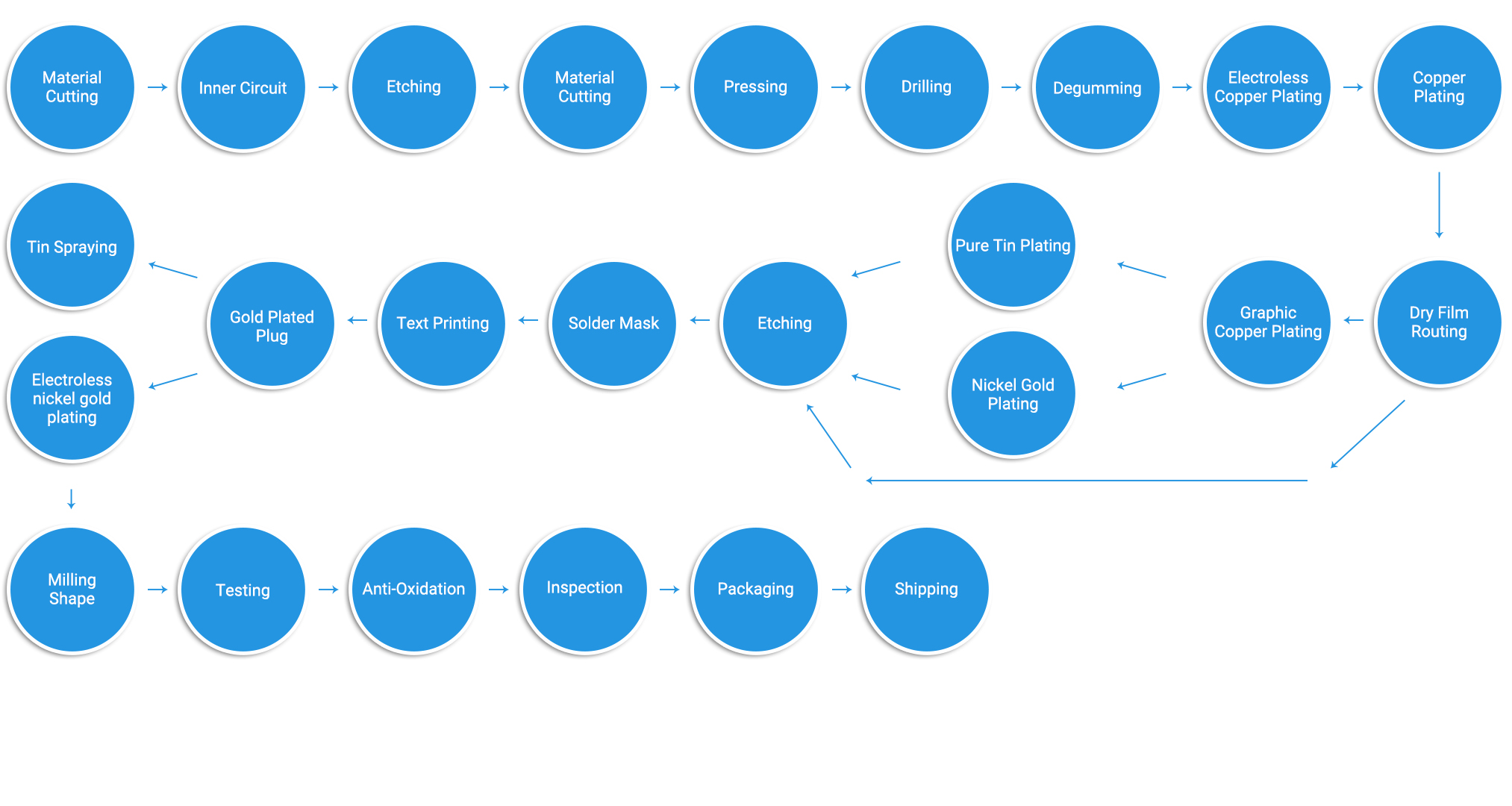

Process Production Video